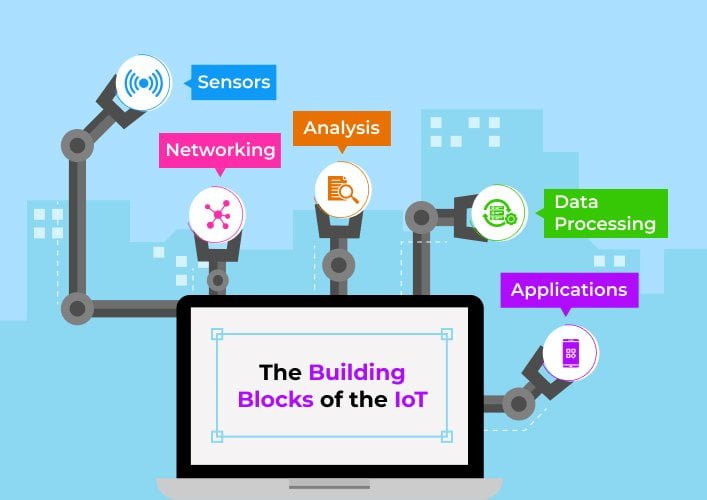

What are the Building Blocks of the IoT?

IoT allows devices to communicate with one another through the internet and perform necessary actions. Some fundamental components of the Internet of Things include:

- Sensors: IoT gadgets use sensors to monitor and record environmental conditions including heat, light, moisture, pressure, vibration, and motion. Wearables, home electronics, automobiles, and even factory machinery all may benefit from having sensors built in.

- Networking: IoT devices use a wide range of connection methods to exchange data via the web and other networks. There are several different wireless networking technologies available today, such as Bluetooth, Wi-Fi, cellular, LoRa, and Zigbee.

- Data processing: IoT devices produce huge amounts of data that must be sorted, analysed, and converted into useful information. Thus, we need to make use of computers and other computing resources like microcontrollers and CPUs that are cloud-based.

- Analysis: A number of methods, including analytics and ML, may be used in IoT data to help draw conclusions and enhance decision-making. Algorithms trained by a machine may examine data and make predictions or improvements to systems

- Applications: Users need to be provided with the observations produced by IoT analytics in a form that is simple to grasp and put into effect. Therefore, users may monitor and manage their IoT devices and operations using a variety of apps.

Why use IoT in Manufacturing industry?

In the manufacturing sector, there are much greater standards expected of workers. Together with the complexity of the supply, there is a powerful and never-ending desire for constant expansion and customization. Additionally, businesses, manufacturers, and product creators are searching for unique techniques to stay ahead of the competition. Let’s understand how the Internet of Things assists in manufacturing.

IoT in manufacturing allows more effective inventory management, more agile procedures, and lower overall operational expenses. For instance, smart linked goods provide you with the ability to examine anything from the sale of things to experiences. Thus, it indicates that you are keeping an eye on how the product is being used in addition to providing after-sale care. Furthermore, the Internet of Things makes it possible to mass customize products and provides a source of real-time data via planning.

Lastly, when there is a speedier and more efficient production process, there is less time spent on each product cycle. For example, with the help of the Internet of Things, jet engine producer Rolls-Royce was able to save clients an amount of approximately $25,000 per plane. With IoT, it collected data and then sent it ahead to manufacturing teams, who improved designs and implemented preventive modeling.

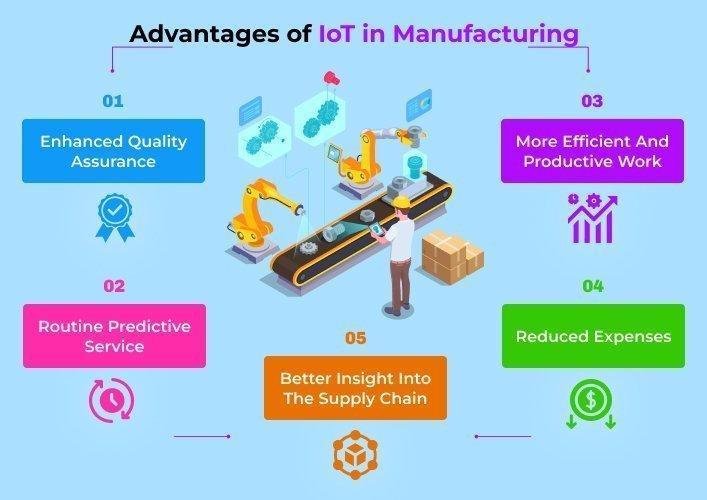

What are the advantages of IoT in Manufacturing?

As mentioned in the above example, using IoT in manufacturing industry has proved to be beneficial. IoT manufacturing software development can help to get various benefits.

Enhanced Quality Assurance

Quality control of production is another area where the Internet of Things might be useful. With sensors, flaws in a manufacturing run may be tracked and corrected instantly. Thus, manufacturers may take corrective action before the quality of their products suffers. Furthermore, sensors can track environmental conditions like heat and humidity in a factory. Thus, manufacturers may take preventative measures if the temperature or moisture levels are beyond acceptable limits.

Routine Predictive Service

By using IoT sensors to check up on machinery in real time, production issues may be seen and fixed before they ever become noticeable to customers. Therefore, manufacturers can predict when machinery may break down by examining data from these sensors. Furthermore, maintenance may be scheduled prior to breakdown, cutting down on costly downtime.

More efficient and productive work

As mentioned above, IoT sensors can check machinery regularly. Manufacturers may enhance productivity and output by evaluating the data collected from these sensors, which allows them to pinpoint inefficiencies, locate obstacles, and implement fixes.

Reduced expenses

There are several ways in which the Internet of Things may help factories save costs. Manufacturers may save money on manpower and boost output by boosting productivity. The costs of repair and waste may be reduced if quality control is increased in manufacturing. IoT in manufacturing may cut down on downtime and maintenance expenses by using preventive modeling.

Better insight into the supply chain

The Internet of Things may also be used to boost the industrial supply chain. Manufacturers may improve inventory management and decrease the probability of excess inventory by keeping track of items and resources in perfect sync. This has the potential to improve customer relations and boost earnings. For instance, manufacturers can keep tabs on goods and supplies as they make their way down the supply chain with the use of radio frequency identification tags.

Conclusion

There are significant advantages of using IoT in manufacturing. IoT is changing the industrial sector in a number of ways, including speed, production, quality assurance, and making good decisions. Thus, manufacturers can maximize efficiency, save costs, and boost customer satisfaction by using IoT analytics.

FAQs

What is a smart factory in IoT?

The smart factory is an integrated network of machines that analyses data, drives automated operations, and increases productivity.

Which are the solutions for IoT in manufacturing?

In the manufacturing industry, IoT helps in the supply chain, energy, production management and more.

Which are IoT sensor manufacturers?

Which are the leading IoT device manufacturers?

What is MES software?

Shivangi is a passionate Copywriter at Alian Software with expertise in technical copywriting. She shares information that is easy to understand regarding business, technology, and trends.