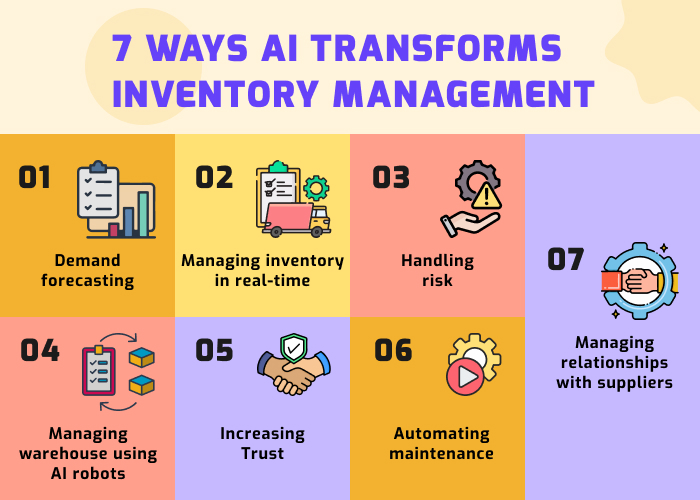

7 Ways AI Transforms Inventory Management

Demand forecasting

Due to AI technology, the predictions of demand have become easy. It uses ML algorithms and examines large datasets in real-time to predict demands. These datasets include customer nature and behavior, and the latest trends in the industry. Furthermore, it can automate business processes as per the demand. For instance, checking the stock levels, ordering the items or getting the items manufactured to prevent getting out of stock, order fulfillment, etc. In short, it streamlines processes to fulfill the demand.

Managing inventory in real-time

Apart from forecasting the demand, AI helps in managing the inventory in real time. For instance, monitoring the inventory across various locations, checking stockout and overstocking precisely, and automating processes for item manufacturing and fulfillment. Thus, the supply chain is optimized and production efficiency increases. Furthermore, it helps in reducing financial loss and gaining profit.

Handling risk

As AI demand forecasting and automation have control over the stock levels of the inventory, managing risk becomes a piece of cake. AI can analyze past, present, and future predicted data. Thus, by analyzing the demand and trends AI helps protect against overstocking and financial loss.

Managing warehouse using AI robots

By effectively traversing warehouses, optimizing picking routes, and automating tasks like order fulfillment and inventory tracking, AI robots facilitate the operation of warehouses. Overall productivity is increased by their capacity to cooperate with human workers and adjust to changing surroundings.

Stockouts may be avoided, surplus stock can be minimized, and accurate demand forecasting is made possible by AI-driven predictive analytics with robotic capabilities. Thus, AI robots provide a more intelligent and flexible warehouse environment where automation and human knowledge work together to ensure optimal efficiency.

Increasing Trust

Blockchain technology’s strength combined with AI increases stakeholder confidence and transparency in inventory management. Ensuring product traceability across the supply chain, blockchain contributes to maximizing inventory visibility for all involved parties. Moreover, every transaction conducted throughout the supply chain can be recorded in an unchangeable, tamper-proof record thanks to blockchain and AI.

This increases accountability while also fostering stakeholder confidence. The decentralized nature of blockchain technology ensures secure data storage and instantaneous data access, hence enhancing the supply chain’s overall flexibility. Error risk is decreased as a result of increased transparency.

Automating maintenance

AI provides equipment predictive maintenance by analyzing sensor data. Companies may minimize downtime and increase the availability of replacement parts in inventory by predicting and avoiding equipment faults.

Additionally, by extending the equipment’s lifespan, AI-driven predictive maintenance makes timely interventions possible. By routinely evaluating the state of their equipment, businesses may proactively plan maintenance procedures to avoid disruptions and guarantee operational continuity. By preventing serious faults, this minimizes costs and boosts overall productivity.

Managing relationships with suppliers

AI evaluates industry supplier performance data and logistics to efficiently manage supplier relationships. Businesses may maintain efficient inventory levels, guarantee on-time delivery, and minimize disruptions by effectively managing these partnerships.

This aids businesses in recognizing potential hazards and opportunities inside the supply chain. By employing predictive analytics to anticipate changes in supplier performance and market conditions, businesses may take proactive measures to adapt. This strategic insight enhances supplier collaboration and creates a more resilient and adaptable supply chain ecosystem.

Trouble faced implementing AI for inventory management

As mentioned above implementation of AI in inventory management has various benefits. However, there are some challenges that you would face while implementing AI in managing the supply chain and inventory. Below are the challenges.

- Complexity: It can be complex to implement AI as it requires time and resources. Furthermore, training the employees to use it takes a significant amount of time. Thus, in solution to that, try to work with an AI development company to develop and integrate the AI-powered inventory management software seamlessly.

- Security: AI integrated with supply chain data is vulnerable to security risks like data breaches and malware. Thus, you need to follow security measures and implement encrypted protocols in the management system.

- Accuracy: AI is not always guaranteed to produce the same results because it mostly depends on precise and high-quality data. Data that is inconsistent or untrustworthy might affect the decision-making process overall and result in inaccurate forecasts. Thus, to avoid this use data quality control processes, audit, and clean databases on a regular basis, and use data validation techniques to guarantee that input data is impartial, accurate, and dependable.

Conclusion

In conclusion, organizations in a variety of industries are seeing new levels of efficiency, precision, and agility because of AI-powered solutions that are transforming inventory management. The capacity to predict demand, optimize stock levels, and automate supply chain procedures has been greatly improved by the integration of sophisticated algorithms, machine learning, and predictive analytics. Consequently, businesses may lessen the possibility of either overstocking or understocking, which will eventually save expenses and enhance overall operational effectiveness.

FAQs

How does AI help in inventory management?

Can intelligent systems manage inventory and shipping?

What role does AI play in the real-time monitoring of inventory?

What impact does AI have on warehouse optimization in inventory management?

Can AI-powered innovations help in minimizing risks in the supply chain?

Shivangi is a passionate Copywriter at Alian Software with expertise in technical copywriting. She shares information that is easy to understand regarding business, technology, and trends.